History

Our fabrication prowess springs from the roots laid by our founding fathers in 1963.We undertook heavy engineering fabrication for erecting tanks for oil installations, depots and tank ages spread all over the country. Over the passage of time, we decided to divide between heavy site fabrication and shop floor engineering.And so was founded Super industries in 1986, and, in 1996 we started being known as Relax Techno Fab.

We are a customer driven company where trust reliability and quality are our forte and an I.S.O.9001-2008 accredited pressure vessel fabricator of 20 years standing.

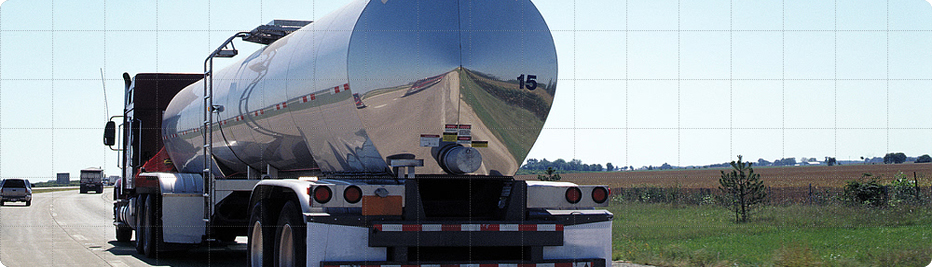

We have a long term supply contract with our customers and focus on the design development and manufacture of all types of transport and storage tanks.

It is our corporate philosophy. Our staff is committed to earn your trust as a reliable business confidante. We have had an active part in this market in the past, but believe this to be a specialized area that has an urgent need to satisfy safety and thru put issues. We take safety seriously and as such RELAX is your source for safe and protective equipment. Prepare yourself for a better way to do business, and when you see our figures of production for the last four years, it will tell you why our customers have been with us for close to 15 years-

| 2006-2007 | 2007-2008 | 2008-2009 | 2009-2010 | |

| Mobile tanks | 101 | 200 | 153 | 271 |

| Storage tanks | 24 | 75 | 24 | 26 |

(Total number of Bitumen tanks made during the top four years is 261) |

||||

COMPREHENSIVE REFURBISHMENT FACILITY FOR TRANSPORT TANKS

Specialist engineering team provides experienced and knowledgeable advise and support for the entire length of purchase of the correct prime mover and the trailer/semi trailer for optimum efficiency and economy of the RELAX package Staffed by qualified technicians, we undertake simple modifications to complete rechassising, and updating of existing combinations. This brings it upto date with the latest industry requirement, matching the Controller of Explosives rules thereby providing cost effective extended operation life.

SHOP FACILITIES

With 21 fabrication bays covering 36000sq.feet of covered area, spread over a plot of 3 acres, we are the biggest shop floor in the small sector.

| 1 | In house drawings and designs through qualified engineers and CAD. | |

| 2 | Radiographic examination facilities. | |

| 3 | Stress relieving. | |

| 4 | Surface treatment, Sand blasting passivation and cladding for glass wool. | |

| 5 | Paint shop. | |

| 6 | Plate bending upto 2.5.mts.width and 25mm.thickness. | |

| 7 | Hydraulic press for Dished end forming upto 20mm.thickness. | |

| 8 | Full fledged lathe shop, shearing and drilling machines. | |

| 9 | Welding machines like Arc welding, MIG welding and Argon. |

INSPECTIONS.

All fabrication work is divided between pressurized and non pressurized vessels fabrication, and as such third party inspection agencies like Bureau Veritas, Bax Counsel Chempro and others certify welding procedures and code standards, where the vessels are under pressure or carry hazchem. All welders are inspection agency qualified and certified, irrespective of the cargo the tanks are likely to carry. We fabricate tanks to ASME section 8 division 1 & 2, PD5500, IS 2825 class 1 and are also open to fabricate tanks to code of the customers choice.

Contact Detail

22, G.I.D.C Industrial Estate,

Ranoli, Dist: Baroda - 391 350

Gujarat. India

Phone: +91 989 888 8877

E-mail: [email protected]

Ranoli, Dist: Baroda - 391 350

Gujarat. India

Phone: +91 989 888 8877

E-mail: [email protected]

very large number of Ethylene Oxide tanks were also made by us, which were a specialized tank class, and the internal wall was metalized with molten Aluminum.

These tanks are non pressurized and are made for carriage of Petrol, Diesel, Low Sulphur Heavy Stock, Kerosene,

We use Stainless 304 and 310 in thicknesses of 8mm and 10 mm, for tanks carrying Methyl Ethyl Glycol, Ethylene Oxide, Phosphorous Oxide,

We were one of the first in India to make underground storage tanks for auto LPG and have made about 160 tanks so far.